CNC Machining Services

Home » CNC Machining Services

Shenzhen Danbes Technology Co., Ltd.

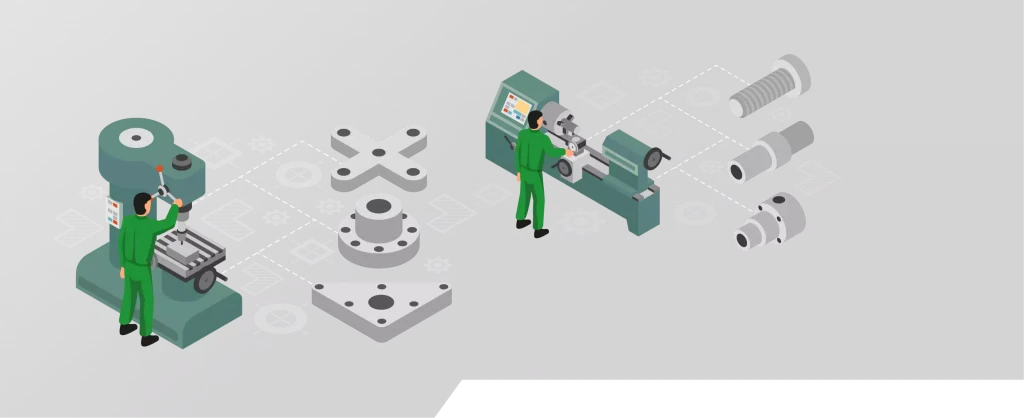

Shenzhen Danbes Technology Co., Ltd. is a high-tech enterprise that integrates R&D, production, and technical services. Specializing in automated equipment processing, precision manufacturing, and injection molding, the company leverages cutting-edge equipment clusters, rigorous workflows, and an exceptional quality management system as its core strengths. We are committed to delivering high-precision, high-efficiency, and customized processing solutions for global clients.

As a high-tech enterprise specializing in precision manufacturing, Shenzhen Danbes Technology Co., Ltd. leverages internationally advanced equipment, a professional technical team, and a rigorous quality management system to deliver comprehensive and reliable machining solutions. With a focus on precision, efficiency, and flexibility, we help clients shorten production cycles, reduce costs, and enhance product competitiveness.

Multi-Axis Machining: Equipped with 4-axis/5-axis 850 series, 1270 series (travel 1200×700), 1370 series (travel 1300×700), and large-scale gantry TZ-2515B (travel 2500×1500), we efficiently handle complex surfaces, irregular structures, and large-sized workpieces.

High-Precision Batch Production: Supports bulk processing of aluminum alloys, stainless steel, titanium alloys, and more, achieving tolerances as tight as ±0.01mm.

CNC turning-milling machines integrate turning, milling, and drilling processes, significantly improving efficiency and consistency for complex parts (e.g., shafts, discs).

Medium-Speed Wire-Cutting: 21 medium-speed wire-cutting machines for precision molds and hard materials (e.g., tungsten steel), achieving surface roughness of Ra1.6μm.

Precision Grinding: Jiande series grinders (KCS-844HD, KCS-3060HD, etc.) support surface, internal, and external cylindrical grinding, with surface precision up to Ra0.4μm.

One-stop solutions from design optimization, prototyping to mass production, catering to both small-batch customization and large-scale orders.

Full-process capabilities including CNC machining centers, CNC lathes, precision grinders, and wire-cutting machines.

Hexagon CMM (8106) and MVP300M optical comparators ensure dimensional accuracy and geometric tolerances comply with ISO standards

U.S.-imported TREK anti-static testers, vacuum leak detectors, and full-range measuring tools (micrometers, pin gauges, gauge blocks) guarantee product functionality and reliability.

24-hour prototyping and urgent order fulfillment to meet dynamic client needs.

State-of-the-art equipment + decade-experienced engineers to tackle complex challenges.

Traceable inspection reports ensure “zero-defect” delivery.

Process optimization and scaled production reduce total costs by 15%-30%.

We look forward to assisting you with your search for optimal solutions. Our team is available to address your inquiries and we appreciate your interest.