Precision Metal Manufacturing Expert

Your One-Stop Solution, Driving Industry Innovation

Home » Metal Processing Services

Shenzhen Danbes Technology Co., Ltd.

Specializing in precision metal processing, Danbes leverages advanced equipment, rigorous management, and masterful craftsmanship to provide end-to-end services—from mold design to finished product delivery—for high-end industries such as automotive, industrial, medical, new energy, and photovoltaics. With a 3,000-square-meter modern facility and ISO9001 quality certification, we are committed to being your trusted partner for core components.

3000㎡

modern facility

ISO9001

quality certification

An experienced engineering team skilled in complex structural design.

Crafting high-precision, long-lasting metal stamping molds.

Laying a solid foundation for efficient, stable mass production.

Equipped with high-performance presses (35T-200T, including brands like SEYI and Chin Fong).

Expertise in stamping various metal sheets (steel, aluminum, copper, stainless steel, etc.).

Capable of handling diverse needs, from standard parts to complex irregular components.

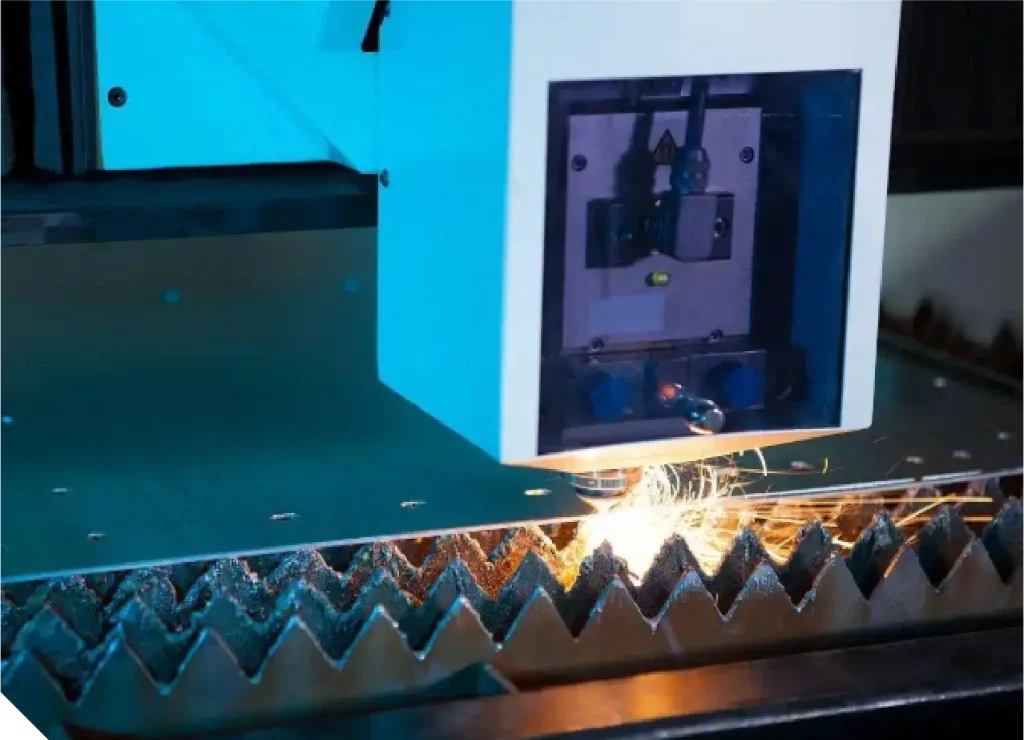

Cutting-Edge Equipment: Featuring Japan’s Amada AE2510NT CNC turret punch, Amada high-power fiber laser cutter, and Amada RG M2 1003 precision press brake.

Delivering complex cutting, precise bending, and efficient forming.

Meeting stringent dimensional tolerances and surface finish requirements.

A professional design team providing solutions that balance functionality, protection, and aesthetics.

Widely used in power, communications, automation control, medical equipment, and more.

Supporting both small-batch customization and large-scale production.

Utilizing advanced CNC equipment for quick response to design validation needs.

Shortening product development cycles and accelerating time-to-market.

Keeping pace with industry trends, focused on R&D and production of high-reliability, high-performance metal parts for new energy applications.

Providing core support for PV mounting systems, battery pack structures, charging facilities, and more.

Continuous investment in top-tier international equipment (Amada CNC punch, laser cutter, press brake, projector, etc.) safeguards high-quality, high-efficiency production.

Strict adherence to ISO9001 international quality standards, implementing the quality policy: “Strict Management, Continuous Innovation, Constant Improvement, Customer Satisfaction.” Equipped with precision inspection instruments like the Ø300mm Wanhao digital measuring projector to ensure zero-defect products.Continuous investment in top-tier international equipment (Amada CNC punch, laser cutter, press brake, projector, etc.) safeguards high-quality, high-efficiency production.

A convergence of experienced management experts and technical specialists, leading a highly trained workforce dedicated to serving clients with pragmatic professionalism and high-precision machining.

Full implementation of 7S management, creating a healthy, comfortable, and safe working environment that ensures production stability and product consistency.

Offering a complete value chain—from conceptual design, mold development, and precision machining to optional surface treatment and after-sales service—simplifying your supply chain.

Whether you require complex mold development, precision stamped sheet metal parts, custom enclosures, rapid prototyping, or new energy components, DANBES is your reliable partner.

We are dedicated to empowering your product success with exceptional quality and efficient service.